Tractorpulling

Turning Weels.

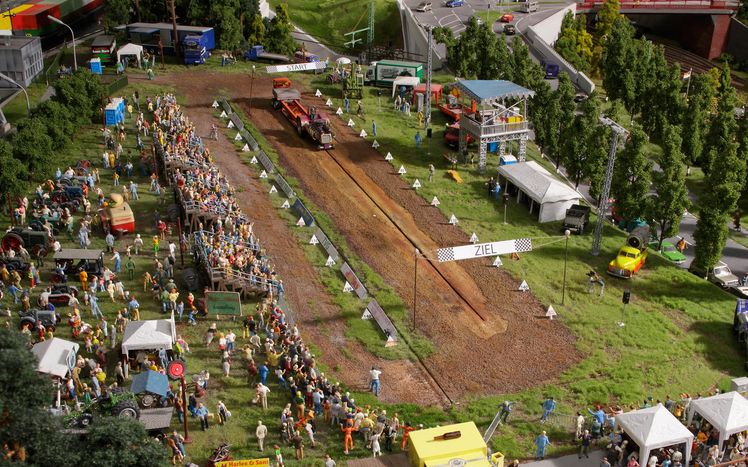

Another technological tidbit among the push button actions is, without a doubt, the tractor pulling in the Bavaria section of Knuffingen Airport. Just like in most realistic cases the tractor here is pulling a so called “weight transfer sled”. This is a trailer with movable ballast, which keeps sliding further to the front over the pulling distance and therefore increasingly stresses a braking shoe. Therefore the cumulative sliding friction steadily increases the resistance of the trailer and, over distance, requiring more and more power from the pulling vehicle and causing the wheels to lose and traction and overrun.

Maybe this was too much advance praise. In the model we depicted the braking shoe and the ballast is really moving on the trailer, but we didn’t want the model to self destruct so the braking shoe is not extended in the model. Instead the technicians went wild on the “climbing” of the tractor: If the hitching point is too high, the frontal weight of the tractor too low or the foot of the driver too rough, the frontal axis will sometimes lift further than driver’s cab height. Rumor has it some of these former tough motored farming machines have been known to continuously rear up.

Of course this wouldn’t happen to our professional miniature pilot, Friedrich von und nach Fahringen, he knows the limits during his rides. On this picture you can see how he, or more accurately a sophisticated mechanic, manages to do so. For all four different movements, driving, climbing, wheel overrunning and movement of the ballast, there are only three engines.

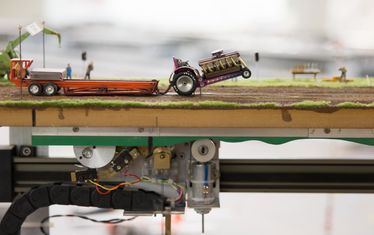

But let’s start at the beginning. Below the surface of the exhibition lies the mysterious technology realm of the shades. Below the tractor pulling area is a slide, running in two tracks and being powered by a stepping motor. This stepping motor precisely controls each movement, since it feedbacks each time it passes one of its magnets (this is called a step and there are several steps to one rotation). On the surface thin poles are attached to the tractor and the trailer, which cut through the surface via a slit. Also attached to the slide are two engines moving the ballast on the trailer. Another engine is moving the back axis of the tractor, simulating the overrun when the resistance of the trailer becomes too strong. By the way, here at the Wunderland all engines and mechanical parts are at least overdesigned by 30% so the parts will not be working at the limit of their capacity. This causes lower maintenance with the necessary servicing for these long term stressed parts.

Only one of the movements for tractor pulling is missing now: the climbing of the tractor. For this Stefan thought up something genius and simple at the same time. Instead of installing another motor which would lift and lower the tractor over a piston rod or something alike and which, with so much short and repetitive movement would wear off very quickly, he found a completely passive solution. A board was sawn on one side in a curved pattern (see picture). On it runs a wheel which is pressed to the board by a spring and which is fixed to the front of the tractor. When the slide drives along its track the wheel goes vertically up and down and with it the tractor as well. This way it was possible to create the climbing without having to program another engine and it runs smoothly. Friedrich is happy.