Chocolate Factory

Where childhood dreams turn into choco!

It is probably the most favorite button among our younger guests: the chocolate factory in Switzerland. One can watch the chocolate production while the little bars are being formed and wrapped in golden paper in the adjacent room. In the end a real little chocolate bar is ejected from an opening at the edge of the model layout.

But don’t get your hopes too high: No, we don’t really produce the chocolate in this tiny factory. Regular as clockwork it is delivered by postal service from Switzerland, where the professionals from Lindt & Sprüngli are responsible for its production. And the chocolate isn’t wrapped here on site either because the health authorities would utter legitimate concern.

Nevertheless, the chocolate factory is one of the highlights in the Wunderland, also because of its sophisticated technology: an entire battery of electric motors powers the vividly moving parts and figurines which depict the different stages of chocolate production and packaging. It requires its own control computer and several engine control circuit boards custom-developed by our technicians. Our depiction of the chocolate manufacturing process from the cocoa bean to the ready bar is based on historical reality. This is how, only decades ago, many chocolate manufacturers made chocolate.

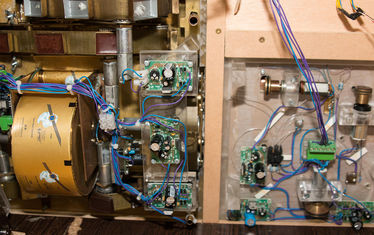

In the picture on the upper right hand side you can see the empty and filled chocolate moulds on a little conveyor belt. The big barrel below is the spool with the not yet cut wrapping paper for the wrapping machine. In the left side of the picture you can see the electronics of the wrapping machine, while on the right hand side you can see the chocolate production electronics.

But the most interesting part is the complex conveyor system, which ensures that in the end actually some real chocolate is ejected from the chocolate factory. In this case we weren’t only striving to depict technology in form of a model but had to find a solution which would ensure real functionality long term. The task sounded very simple at first: Take a piece of chocolate from a storage unit and transport it to the exit for ejection on the side of the layout.

The first problem was to find a solution that would work for many years. The second problem was the light weight of the chocolate bars. And with our first set of mechanics problem 2 led to problem 1. Therefore we renovated the entire conveyor system in 2014 and all the Wunderland team learned a new word: spiral conveyor. But first things first:

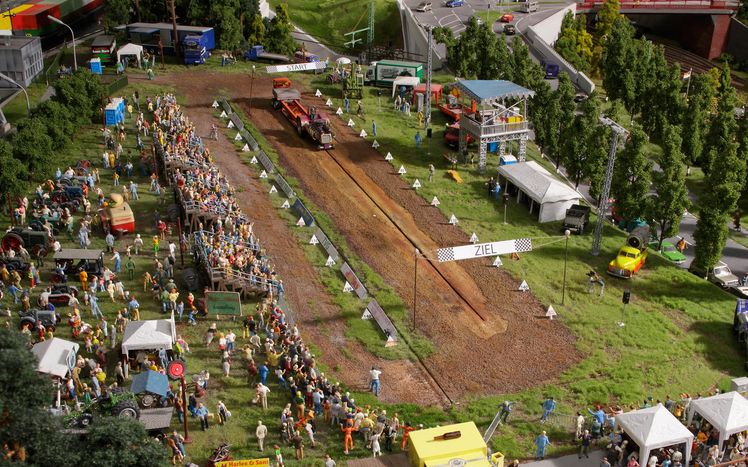

In the top right corner of the picture you can see the storage container for the chocolate bars. It is made from acrylic glass so it is easier to check remaining chocolate. From this container the chocolate bars are transported into the big bowl in the middle. This is the so called spiral conveyor. A upwards spiralling lane leads from the bottom to the top of the bowl along its outer wall. This is for the separation process, to make sure only one bar of chocolate in ejected at a time. For this process the entire bowl is vibrated, the vibrations leading from top to bottom, against the direction of the conveyor belt. Like magic the chocolate bars move up the conveyor one by one to meet a second conveyor belt. You can compare the movement of the vibration to the one tossing a pancake in the air to flip it over.

Once a bar of chocolate has passed a photo sensor at the top and has moved onto the next conveyor belt, the process is stopped. Now the bar needs to be delivered to the point of ejection. The light weight of the bars leads to very little adhesion on the steep conveyor belt, which regularly led to the bars sliding back down. To keep the bars from sliding we mounted little struts, so called lifters, horizontally onto the belt which drive the chocolate bars to the top.

All of this stays invisible for the guests: for them it's only real chocolate coming from the factory.