Catapult

Or: How to make model airplanes fly?

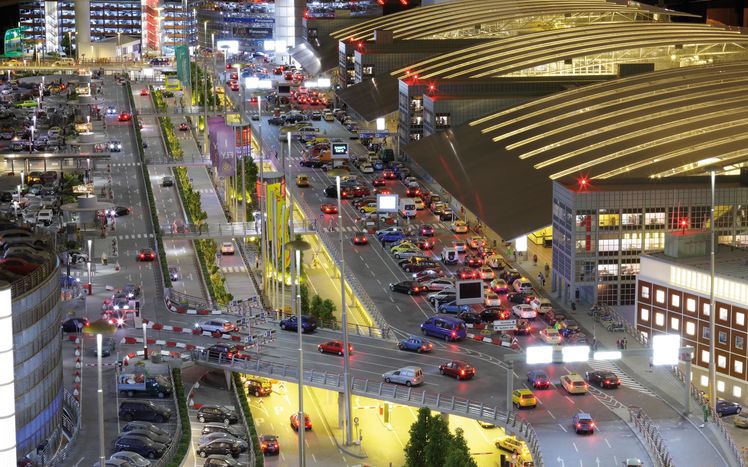

A large part of the development work at Knuffingen Airport was about the task of realistically portraying the taking off and landing of the air planes. Basically our airplanes are like big Carsystem vehicles: they follow a wire in the roadbed with the help of a steering magnet and are self-powered. This is great because it enables the planes to move individually on the airfield. But we didn’t want to simply let the planes drive up a Plexiglas ramp because it wouldn’t have looked very realistic.

Therefore we started experimenting with different possibilities to let the air planes take off and land by an external mechanism. And to thereby make it look as though they would really fly through the air.

The visually most appealing solution would have been to hang the planes from razor thin nylon threads and pull them upwards on take-off. But then the question arose where to leave the threads once the planes had landed? The biggest problem which made us dismiss this version as well as several others was the lack of precision. After touch down an airplane has to land precisely on top of one of the lead wires of the Carsystem in order to drive independently on the ground. And the same challenge occurred vice versa. Before take-off we needed to position them in a way to allow the fly mechanism to “grab” them.

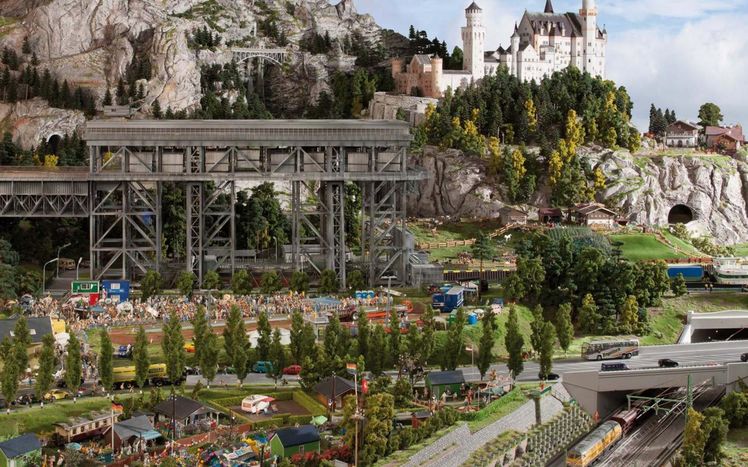

The latter problem was eventually solved by fine tuning hardware and software of the Carsystem, making the airplanes accurately reach their landing position each time. But the question of take-off and touch down remained. After meticulously puzzling for a long while a solution was found which was more than just a compromise between visually staying realistic and technologically meeting all the necessary demands: our catapult. This is what the device is called which is found on aircraft carriers underneath their short runways to make airplanes start nevertheless. After this we also named our own unique take-off device.

For this, the manufacturer of special machines, Bosch Rexroth, built a carriage system which is located below the runway. From this carriage two pole emerge, “skewering” the plane before take-off, by driving into two tandem holes on the lower side of the plane body. Two poles are necessary so the plane will not twist and lift off realistically nose first. Both poles have individual prompting and together lift the airplane off the runway.

Still the plane needs to move along the runway horizontally as well. This is where the carriage comes in. After the airplane has taken its starting position and been skewered by the two poles, the carriage moves with realistically increasing speed down the runway, while the poles let it lift off and rise.

In order to cover up the relatively wide slit in the runway, through which the poles emerge at take-off we close this slit with special covers. These open just before the moving poles and close again immediately behind them. With this we have created the first self-repairing runway in the world! The movements of the carriage and the two poles are different for each plane, since e.g. a small propeller plane lifts off more quickly than a big Airbus A380.

Upon landing, the process repeats backwards: every plane lands true to type, then arrives and comes to a standstill at the designated spot and the poles retract from the airplane and sink below the runway surface. From then on the plane moves individually controlled across the Carsystem routes of the runway towards its assigned parking position.