Our Technical Workshop

Department CRASH! BOOM! FLASH!

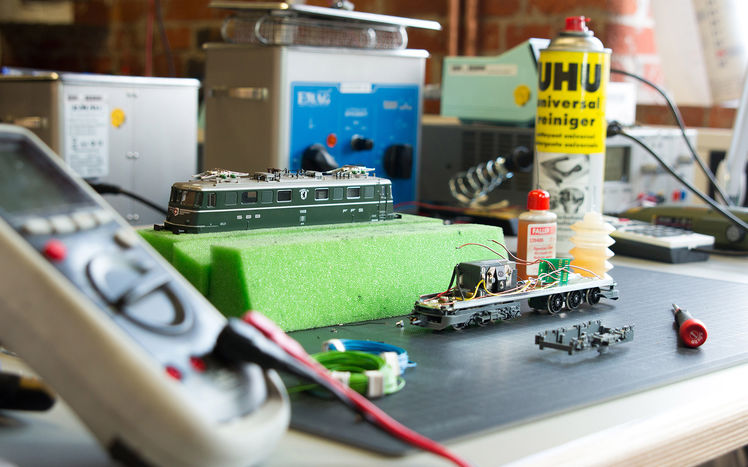

Quite a few people claim the technical workshop to be the true heart of the Wunderland. In any case, it’s the birthplace of many of the most favorite attractions and animated scenes in our different theme worlds.

It is divided into two parts: the train technology is responsible for the wiring and technical maintenance of the model railway. This means in particular building in the tracks, the signals and the contact wiring into our newly constructed sections and to service and maintain, and should need be replace, those same things in the older sections. This is why we see a lot of technical employees crawling underneath the displays and sometimes on top of the currently in construction Italy theme world.

Adjacent to the technical workshop is the mechatronical and electric department, where our employees and helpers are responsible for anything besides the railway tracks that lights up, drives around, flies up, fights or produces chocolate. When constructing a new theme world, the technicians work closely with the model makers, developing and building electronic and mechanical elements in the models, so that in the end the streetlights will really light up, the vehicles and houses will be realistically lit and all the push-button actions will work without problem. On top of that the electricians are also responsible for the so called “e-corner”, where all lighting and motoring is orchestrated from and provided with energy.

Everyone who ever visited the Wunderland probably realized the many push-buttons, which enable visitors to control little parts of the display and bring additional action to it. But only few know how much work, brain wise as well as handiwork, is put into these little sceneries. The tow away truck in the HafenCity for instance took 250 hours to install the mechanicals, lights and to do the programming. In most cases though, the initial conception phase is what takes up the most time. The mechanism, allowing visitors to have a look inside the Elbphilharmonie, took 400 hours of work. And we don’t want to start talking about all the effort we put into making the eruption of the Vesuvius as realistic as possible. All these push button actions have to be maintained as well. This is why every morning, before we open our doors, the devices are being tested, and if need be, repaired. Most problems arise from wear or defects in the engine.

A team of its own is responsible for building new airplanes, as well as maintenance of all airplanes and the technology of the airport (for instance the catapult underneath the runway). Bigger airplanes are mostly pulled in for inspection once a week, the smaller ones every two weeks. Besides this we are of course building many new airplanes. Each plane takes a month to build, with waiting time between the production steps, for example when coats of paint are applied.

On your next visit feel free to drop in and have a look at the open part of the technical workshop on the third floor. Maybe you can catch a glimpse of one of our secret new attractions…