Formula 1

What a challenge developing our miniature Formula 1 really was! Here are some exciting insights, facts, and figures about the technology behind the big race.

From first attempt to masterpiece

What was a vision for over eleven years is now doing laps in the miniature world of Monaco, without rails, without visible technology, but with full racing action. And even Formula E drives every third race. The 1:87 scale Formula 1 track is one of the most elaborate projects ever realized at Miniatur Wunderland. There were many setbacks, but in the end, the motto was: persevere, tinker, keep going. The result is a racing facility that is unparalleled worldwide: technically brilliant, incredibly precise, and fascinating in every detail.

At the very beginning, a portable toilet was used as a test vehicle on the track – not kidding! Even though atypical vehicles such as Sonic, Lightning McQueen, and Ed Euromaus like to stray onto the race track, the races in Mini-Monaco are much more professional today: pit stops, safety car phases, spectacular overtaking maneuvers – everything is there. It was a long road to get here, because a completely new technology had to be developed for the freely driving cars. Conventional systems could no longer keep up with the requirements for precision, speed, and realism. Especially since the car system already known in Wunderland could not be adopted, as Formula 1 vehicles offer no storage space for technology.

Magnet technology as the key

The trick lies – literally – beneath the surface: tens of thousands of copper tracks form tiny windings that generate precise magnetic fields. These fields “pull” the cars along the track, depending on which winding is currently active. Each of the small race cars contains a so-called Halbach array, a special magnetic arrangement that is also used in magnetic levitation trains. This allows for completely free movement – no rail system, no predefined routes, no tricks. On the 22 m meters of race track, 24 track boards, 90 drive boards, and 90 location boards, 1,080 microcontrollers, 5,700 location sensors, and 2,800 temperature sensors ensure that each vehicle can follow its own path – with everything that goes with it: from tire wear and braking behavior to pit strategy.

Complex technology in the background

The software running in the background is almost a minor miracle in itself: it calculates several hundred thousand parameters per second. This allows the cars to react to race conditions in real time, meaning that no two races are ever the same. Each car has its own program and is controlled individually. Even the small bodies are real eye-catchers: Each car takes over 60 hours to build, paint, and decorate with up to 150 stickers—because it's the details that matter.

To ensure that the audience doesn't miss out, 29 live cameras provide exciting perspectives along the route – broadcast on 11 monitors in the middle of the Monaco backdrop. A total of over 39 kilometers of cable was laid and more than 100,000 lines of code were written. The effort involved? Over 150,000 working hours.

And now? Full speed ahead!

Incidentally, miniature Formula 1 technology will soon be used in a new project: in collaboration with Europa-Park, a mini roller coaster with a loop is being built: Voltron, based on the actual construction plans from Europa-Park. Here, too, the traveling magnetic field is being used, but this time to counteract gravity. The new 1:87 scale ride will be around four meters long, making it the largest mini roller coaster in the world.

Find out more:

Dive deeper:

-

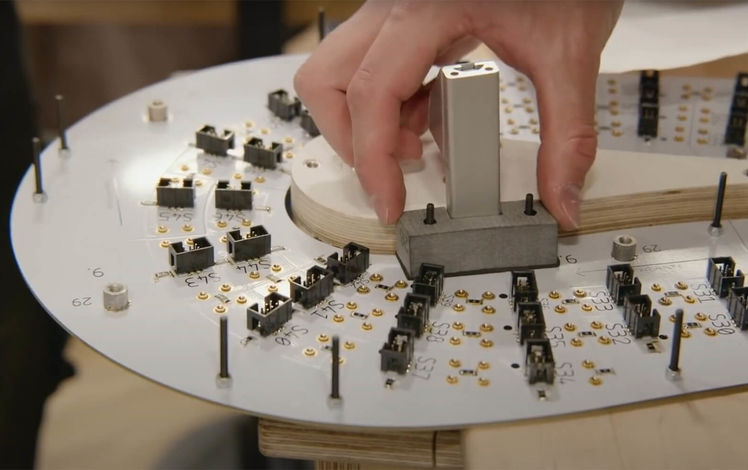

How the Formula 1 track works

![Monaco formel 1 strecke leiterbahnen]()

The track consists of many, many high-current conductor tracks and many control boards with feedback systems. These are used to measure the average current flow generated by the moving cars using current sensors. This information is then forwarded to a computer so that the tracks can be monitored and controlled properly. The driving logic alone requires 200-300 microcontrollers, and the feedback system requires 2000-3000. In total, there are over 1000 components on one circuit board, and it takes over 1.5 days to assemble them. However, the challenge in route planning also lies in the material, as the 22 circuit boards must be seamlessly connected to each other. If this is not the case, it will cause disruptions in the driving behavior of the cars.

-

Construction of Formula 1 cars

![Monaco formel 1 autos bau]()

Although we have the original 3D construction data for the Formula 1 cars from Monaco, this is of little use to us at a scale of 1:87. If the cars are scaled down to our scale, certain components become so delicate that the material thickness approaches zero after shrinkage. Therefore, all cars were designed independently by our team. It takes about 50 hours to draw one car.

Once all 20 cars have been painted by the model makers and fitted with the appropriate decals (stickers, foil), they are passed on to the model engineering department. Here they are fitted with the Halbach array and wheels and are run in.

At the start of a new season, i.e., when new Formula 1 cars and new designs have been completed in Wunderland, old cars that are reused in the new season due to their similarity to the previous season are reset in their statistics. Data such as the number of victories, number of races, and laps driven are reset so that the game can start from 0.

-

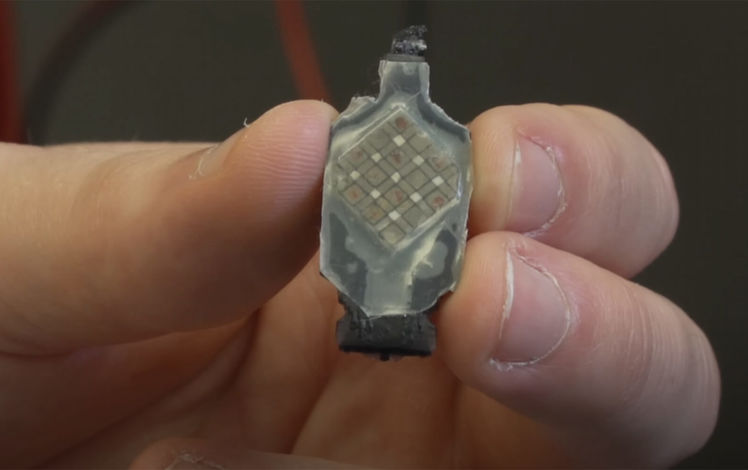

How Formula 1 cars work / The Halbach array

![Monaco formel 1 halbach array]()

The Halbach array on the underside of each vehicle consists of a special arrangement of over 20 permanent magnets with different polarities. Named after German physicist Klaus Halbach, this arrangement concentrates the magnetic field on one side, in this case downwards, while it virtually disappears on the upper side. This creates a strong, one-sided magnetic field that acts specifically in the direction of the coils under the track.

When current flows through the many conductor tracks in the track, the car's magnet is automatically attracted to where the fields are active. The high number of conductor tracks and control by countless high-speed microcontrollers guarantee precise driving of the cars.

The magnet fields in the track conductor tracks, which vary locally due to controlled current pulses, are in constant interaction with the Halbach arrays of the vehicles. This attracts the vehicles magnetically, allowing them not only to be held stable on the track, but also to be moved with high precision.

The combination of Halbach arrays and actively controlled conductor tracks thus represents an innovative form of contactless, low-wear, and highly accurate vehicle guidance.